Products Texas

Total Elemental X-ray Analysis System

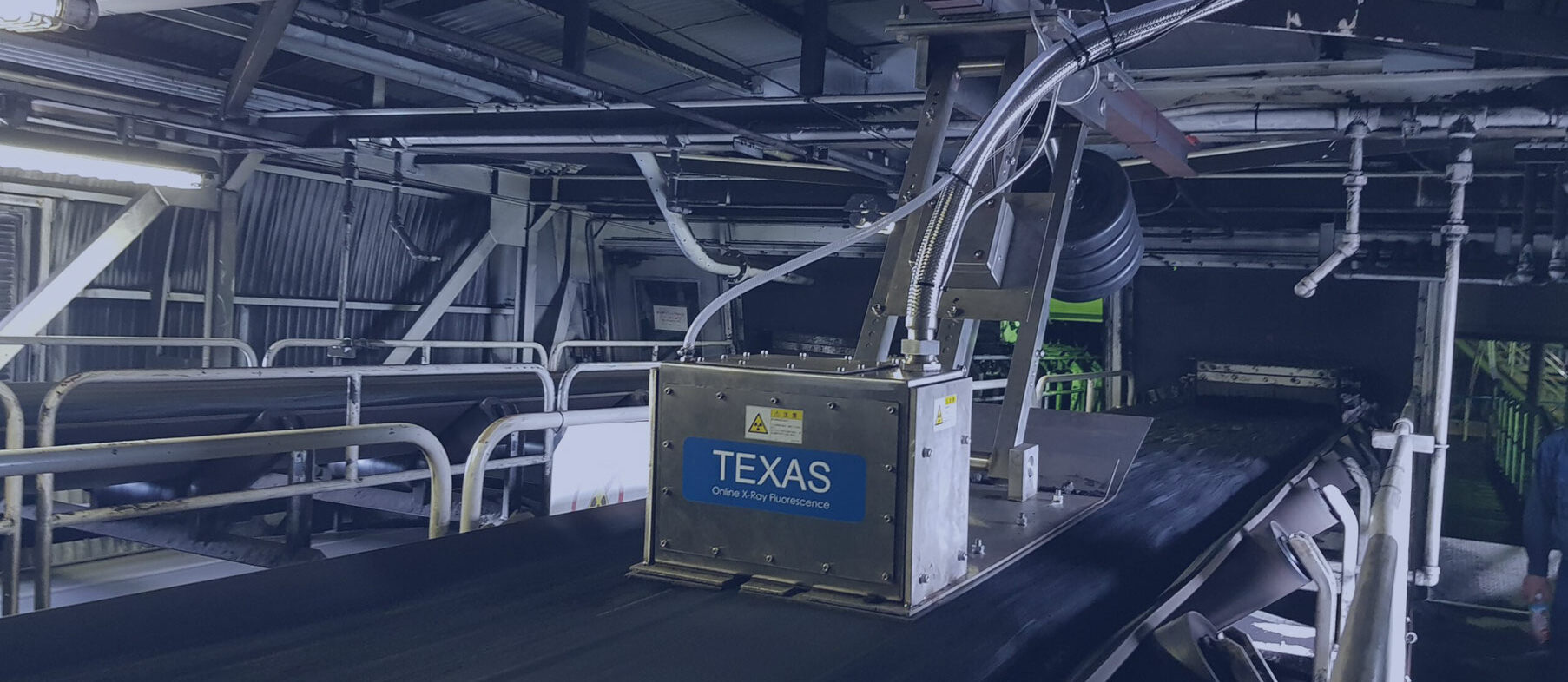

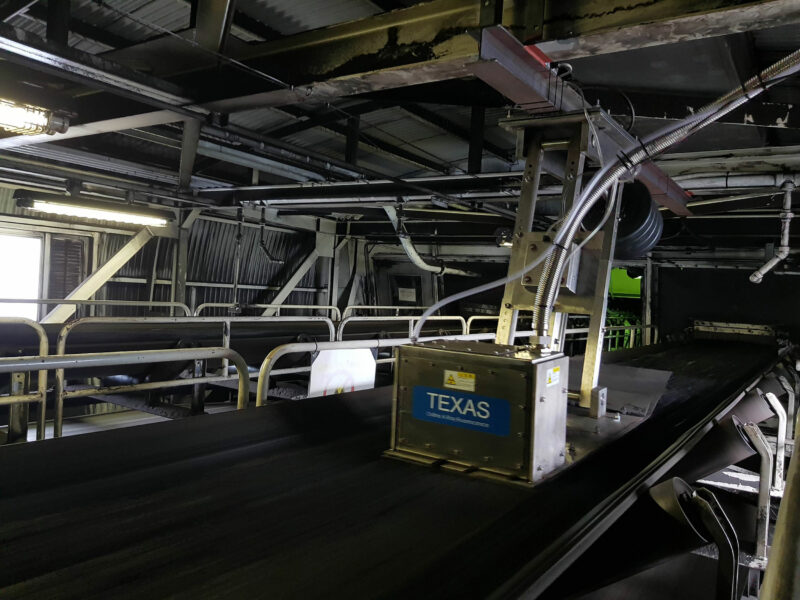

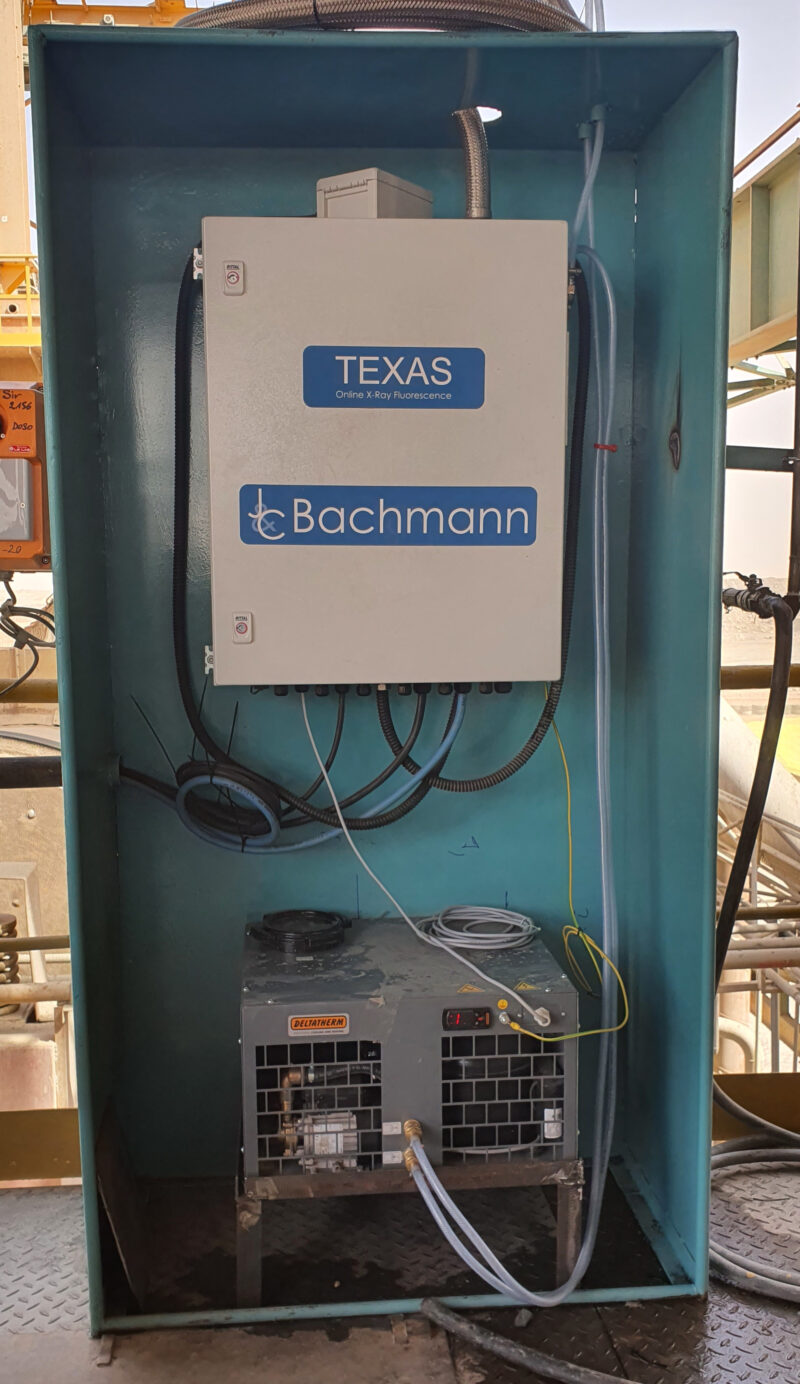

TEXAS is an online X-ray fluorescence device for the elemental analysis of bulk materials without sampling.

It can be mounted above main conveyor belts or at other feeding devices and analyzes continuously the elemental composition (Z>12) of the material.

The device is used as a tool for process control. It offers immediate information (24/7) about the process without time consuming sampling and analysis in the laboratory. However, it does not replace the laboratory but serves as a process tool for feed forward or feed back control.

The device is equipped with a rugged X-ray tube and a energy dispersive detector in a stainless steel box. The information acquired with the sensor is processed with the software suite MONACO by an industrial PC which can be linked to the control system by standard interfaces.

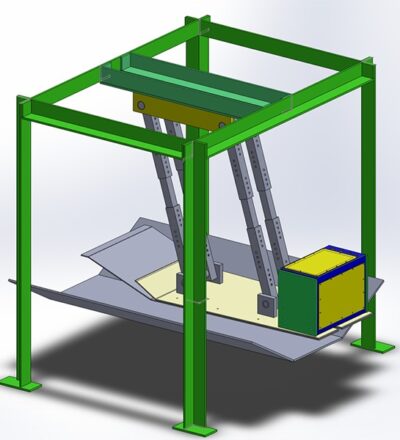

TEXAS Chute Monitoring

Free falling coarse material or powder can be monitored in chutes. TEXAS will be mounted at a side wall where a window is inserted into the chute. The measurement is done continuously as long as material is inside of the chute. If the chute is empty then the measurement will be suspended.

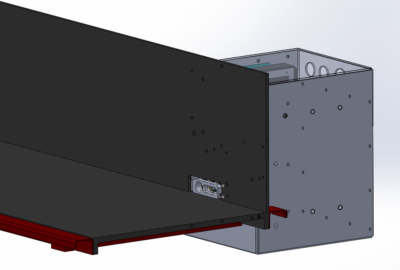

TEXAS at airslide

Fine material is often conveyed using an airslide. The system is completely closed; material cannot be accessed easily. However, using a small window at the bottom of the airslide allows TEXAS to monitor the material which moves along.

This setup is ideally suited for base metal matte.

| X-ray tube | Ceramic, maximum voltage 65 kV |

| Detector | Silicon drift detector with internal cooling |

| Sensor enclosure | 400 mm * 300 mm * 220 mm, stainless steel |

| Software | MONACO evaluation suite with SQL database |

| Operating temperature | -20 - 45 °C (environment) |

| Electrical cabinet | Stainless steel cabinet, IP 65 600 mm * 600 mm * 250 mm |

| Computer | Embedded Computer OS Linux Web Interface |

| Interfaces | Modbus Other interfaces (serial, IP, Profibus) optionally available |

| Air condition | Solid state cooling unit for sensor/XRT |

| UPS | Uninterrupted power supply for power conditioning optionally available |

| Power requirements | 110 V/230 V, 1000 W |

| Belt width | 400 - 1.800 mm |