X-ray Analysis: XRF and XRT

Many of our devices use X-ray radiation to obtain measurements. There are two major modes of operation used in our devices: Some devices use XRT (X-ray transmission) while others use XRF (X-ray fluorescence).

In XRT the X-rays go through the analyzed material, the most well-known XRF applications are in medical imaging and airport security. Strictly speaking, these are two different XRT applications because medical imaging is usually a single energy measurement whereas airport security will perform a dual-energy measurement. J&C Bachmann offers single energy XRT devices (such as CALGARY) as well as dual energy XRT devices (such as OREGON).

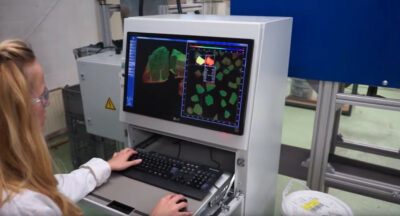

In XRF the X-rays do not go through the analyzed material, but instead interact with the surface of the material, triggering the emission of secondary X-rays characteristic for the chemical elements in the material. The characteristic radiation can be measured using an energy dispersive detector indicating the elements in the material and their concentrations. J&C Bachmann offers various XRF systems for industrial use, such as TEXAS, FLORIDA, or IBERIA.

Example Applications

- elemental analysis of solids and liquids

- measurement of layer thicknesses

- measurement of material thicknesses (steel tape, paper etc.)

- measurement of density in slurries

- image analysis (disbonding, cavities etc.)

Radiation Protection

XRF and XRT are non-destructive procedures. X-rays do not change or influence the material properties of the analyzed material. Nonetheless, in the human body, ionizing radiation such as X-rays can cause mutations in the DNA, and therefore might lead to cancer later in life. This is the reason why not only there are strict dose limits for ionizing radiation, but the ALARA principle must be applied. ALARA is an acronym for “as low as (is) reasonably achievable,” which means making every reasonable effort to maintain exposures to ionizing radiation as far below the dose limits as practical. We take radiation protection very serious at J&C Bachmann and make an effort to keep exposures far below the limits.

Two properties of X-rays make them even better to handle than other forms of ionizing radiation that is sometimes used in other industrial measurement devices. Firstly, X-rays can be efficiently shielded by reasonably thin (few millimeters) of metal, so that typically there is no measurable radiation outside of the device even when in full operation. And secondly, because X-rays are created from electric power, just like electrical light, the radiation will completely stop when the power is unplugged, resulting in a save state.